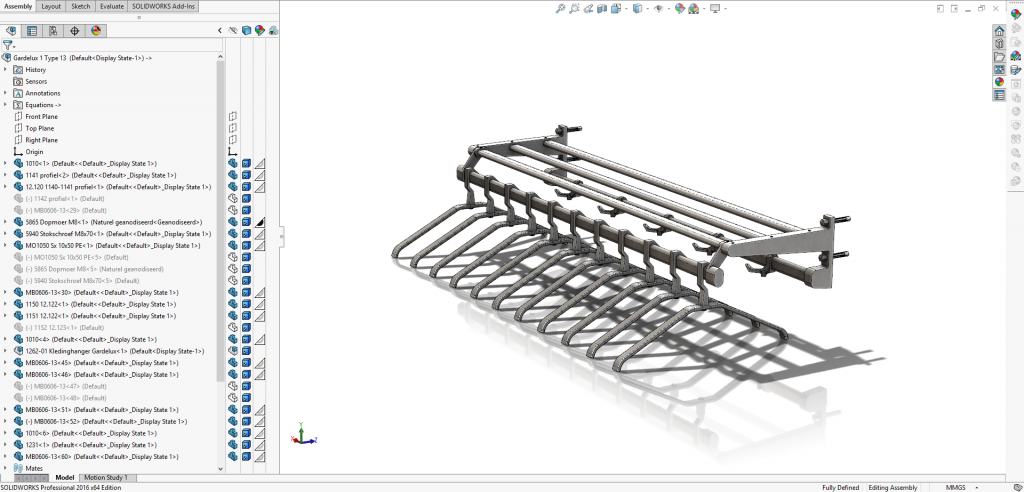

One of the things I like to do most, is automate workflows. Specifically 3D-CAD and/ or BIM workflows.

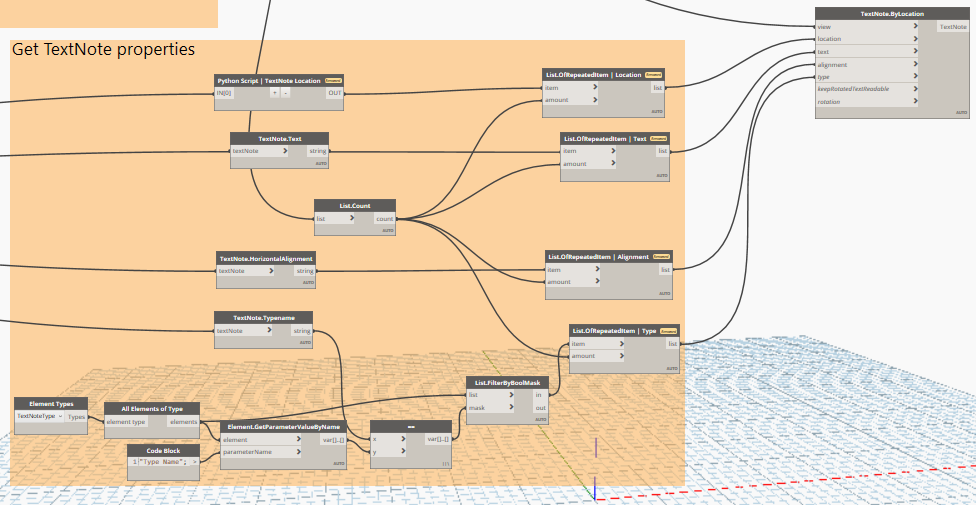

Dynamo for Revit is a visual programming tool which allows for this type of automation.

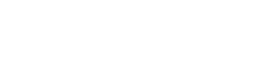

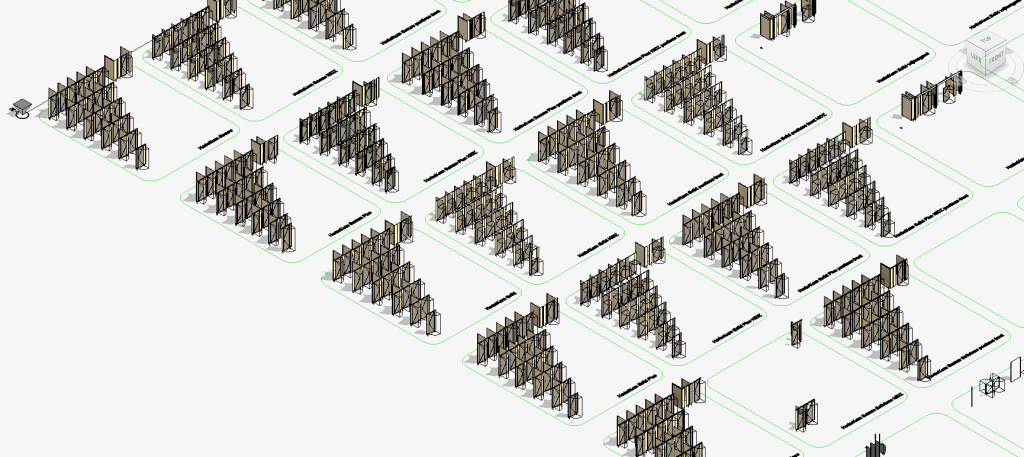

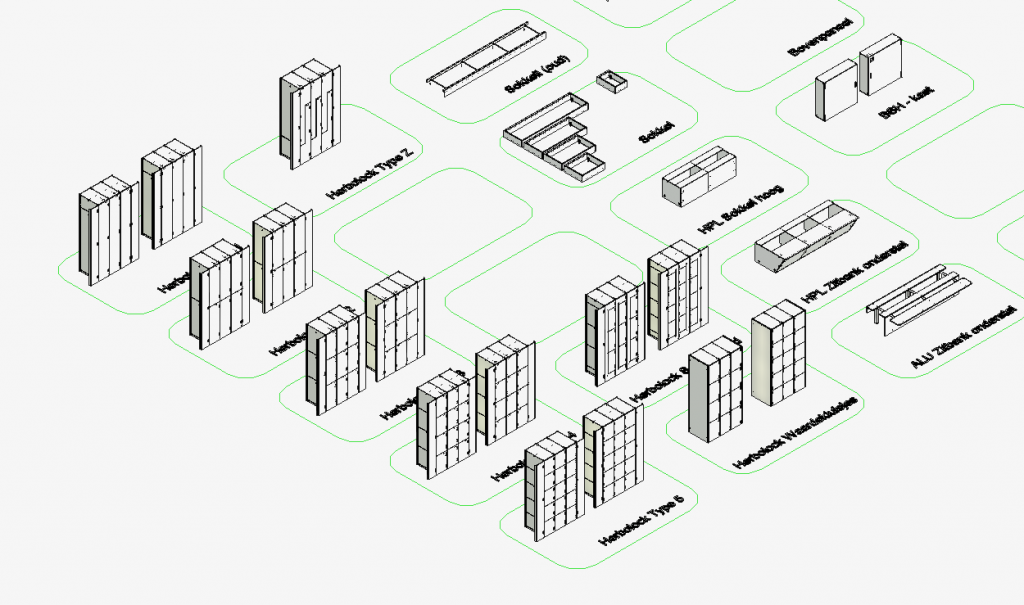

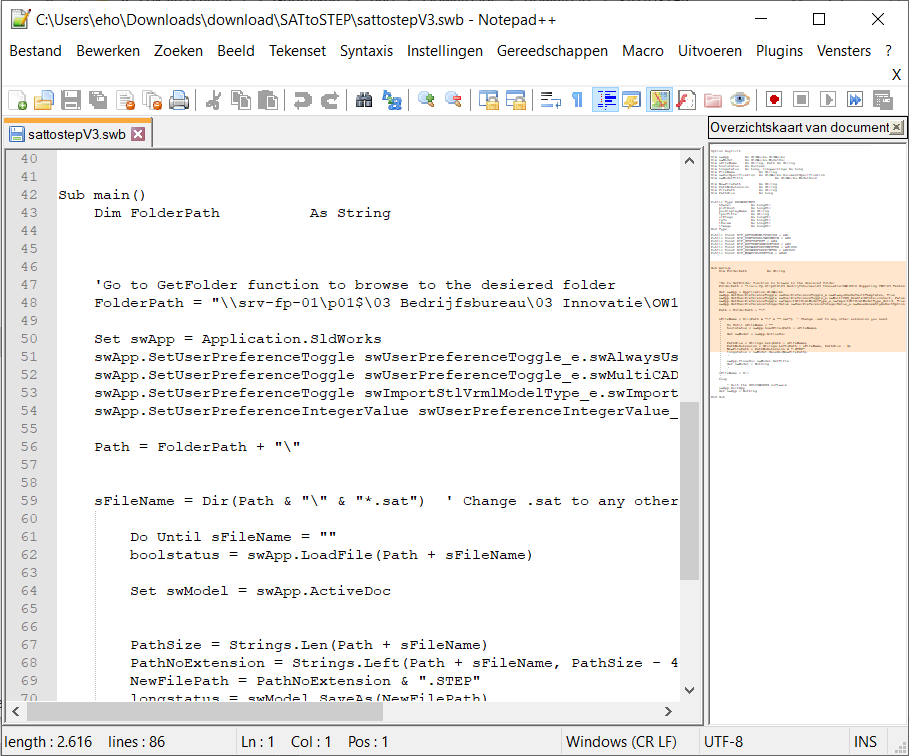

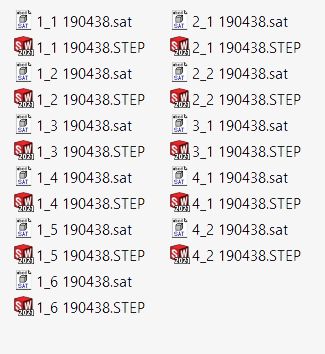

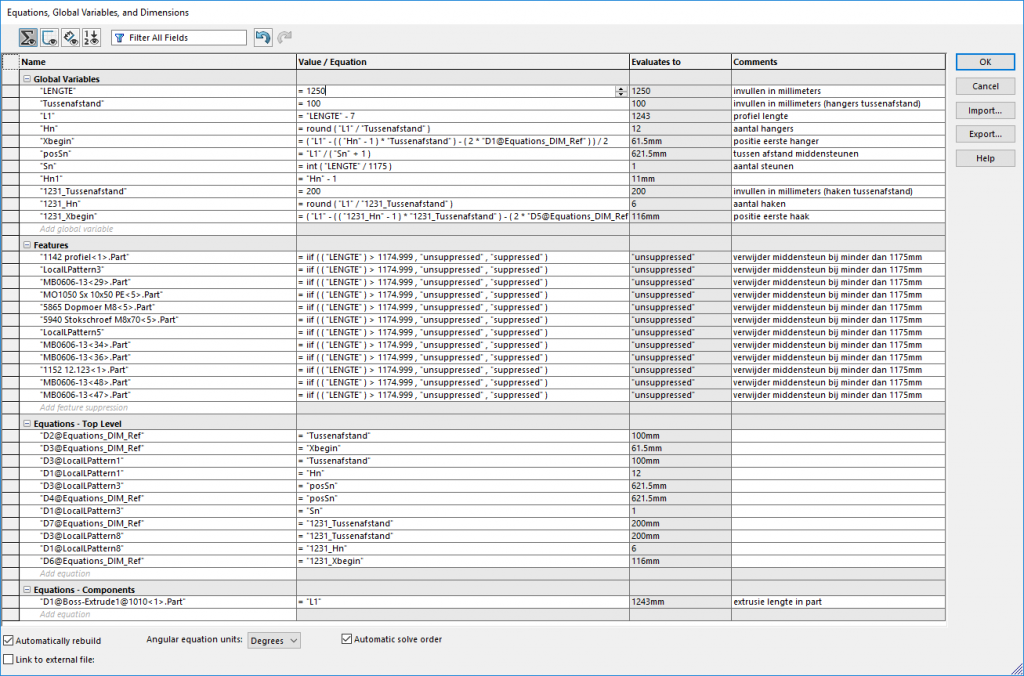

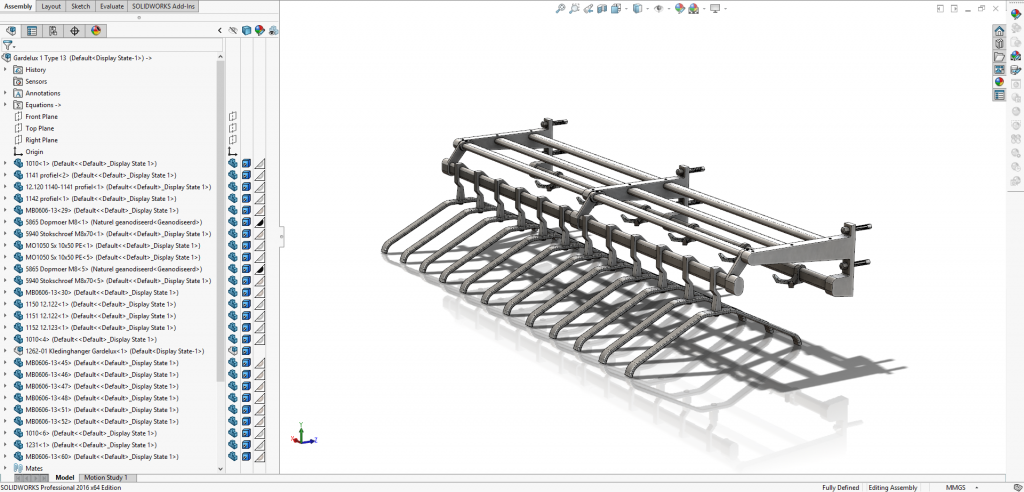

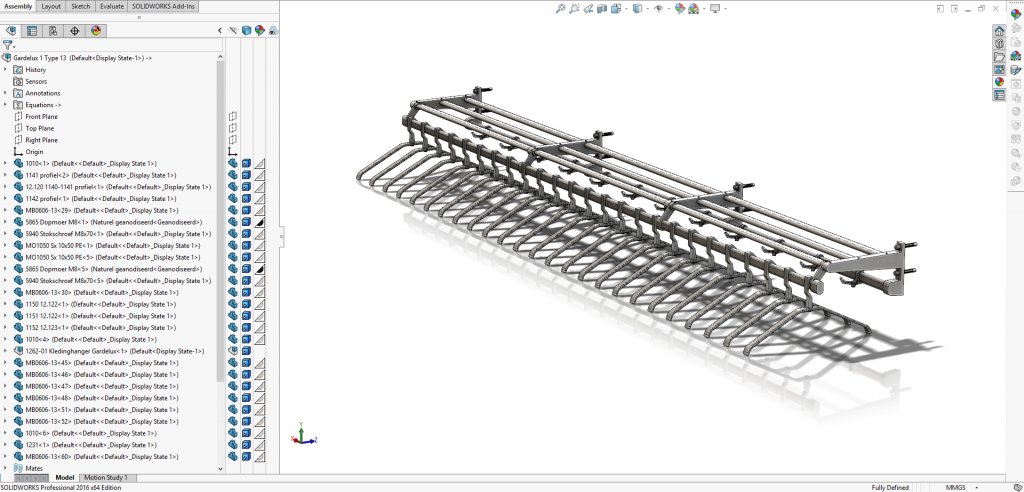

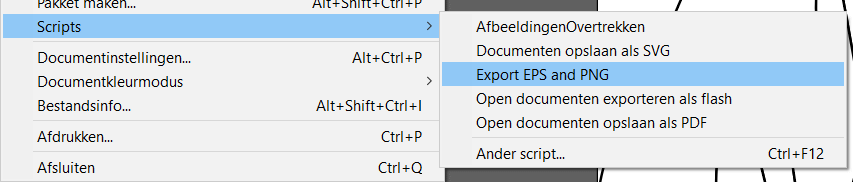

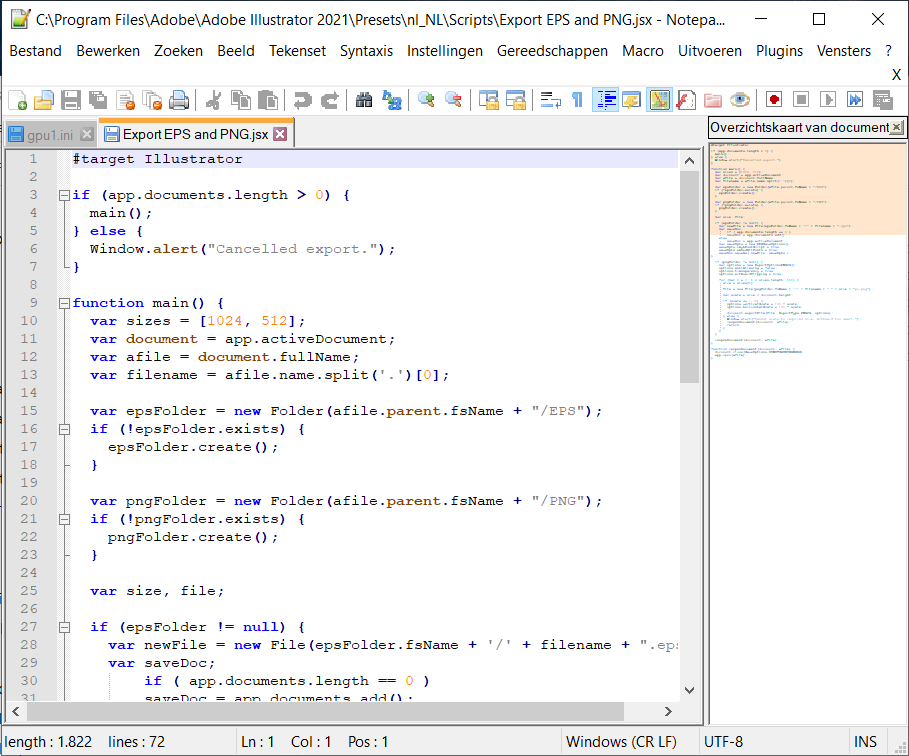

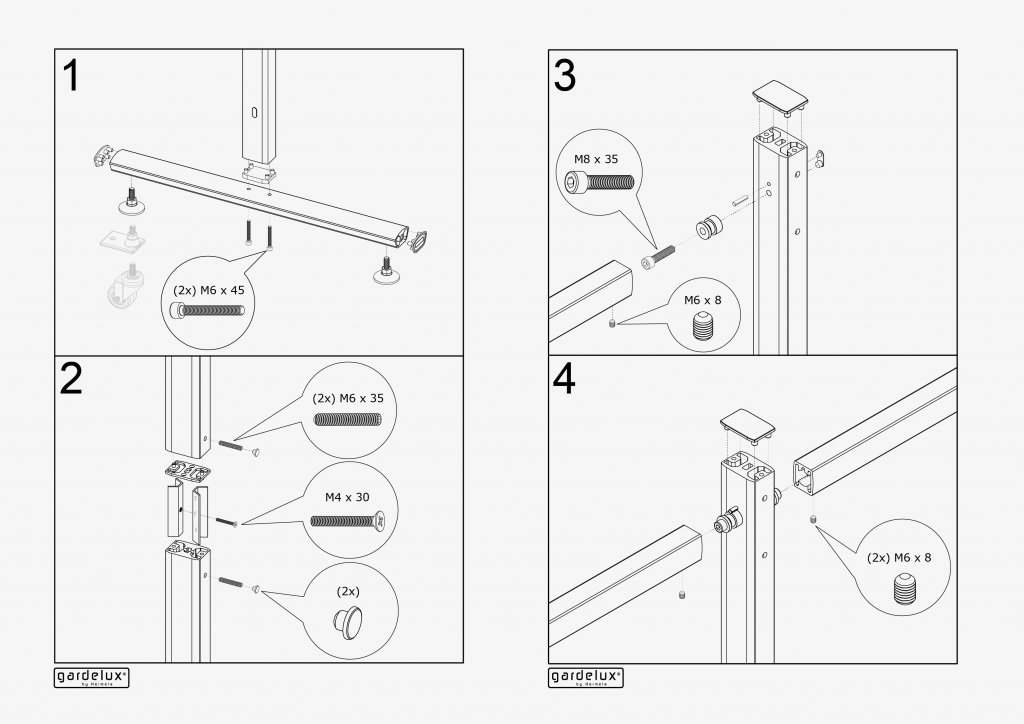

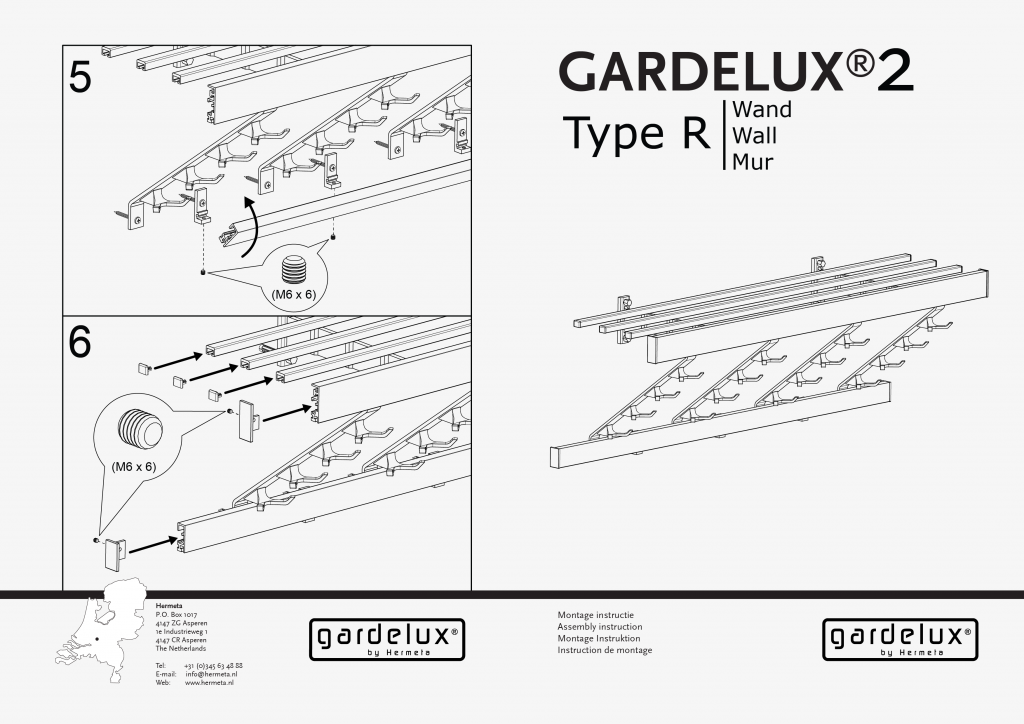

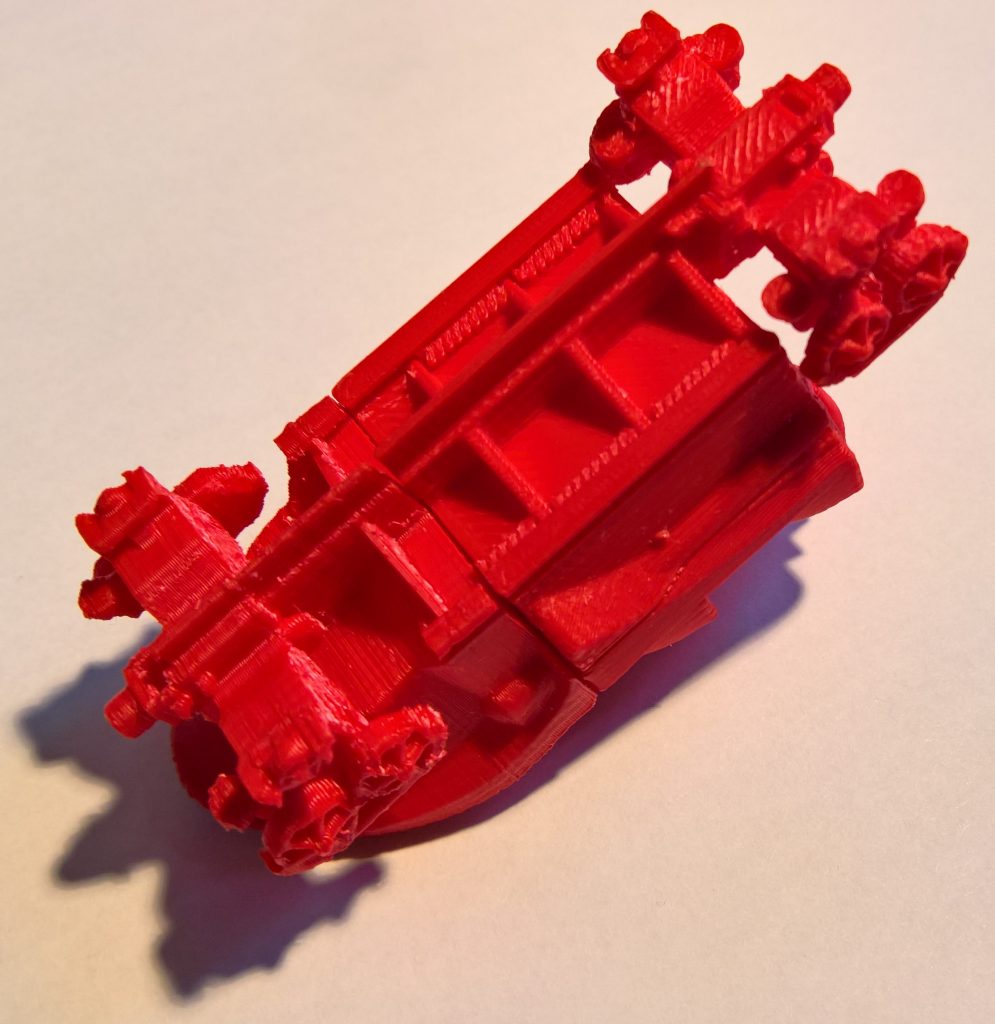

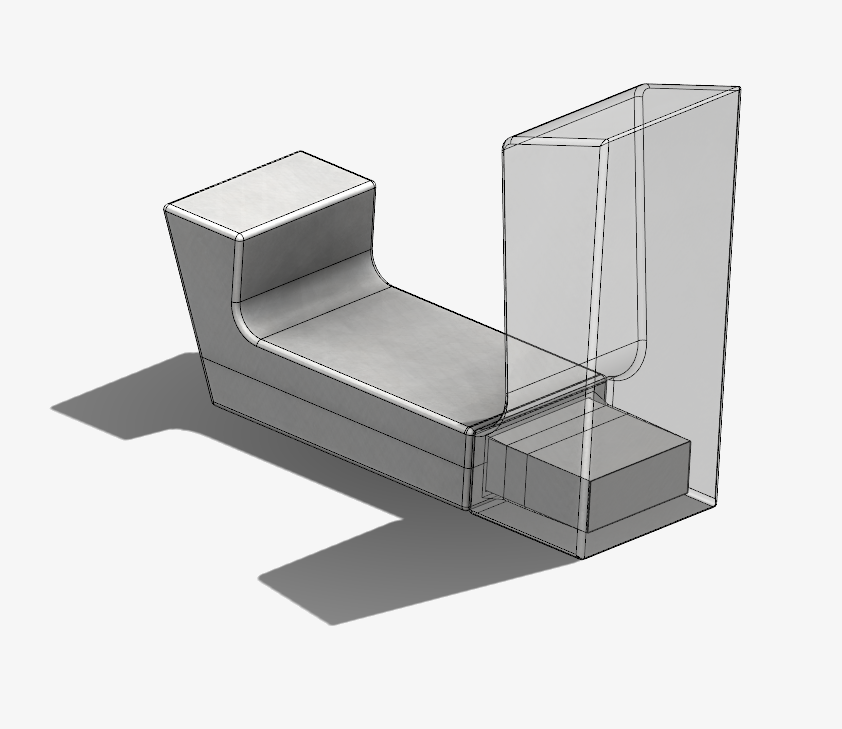

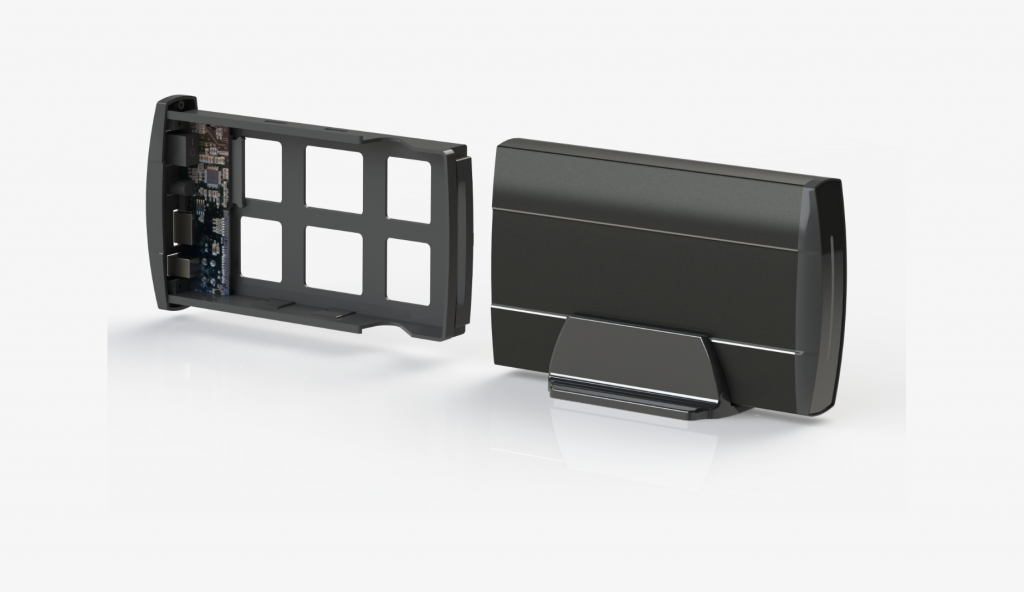

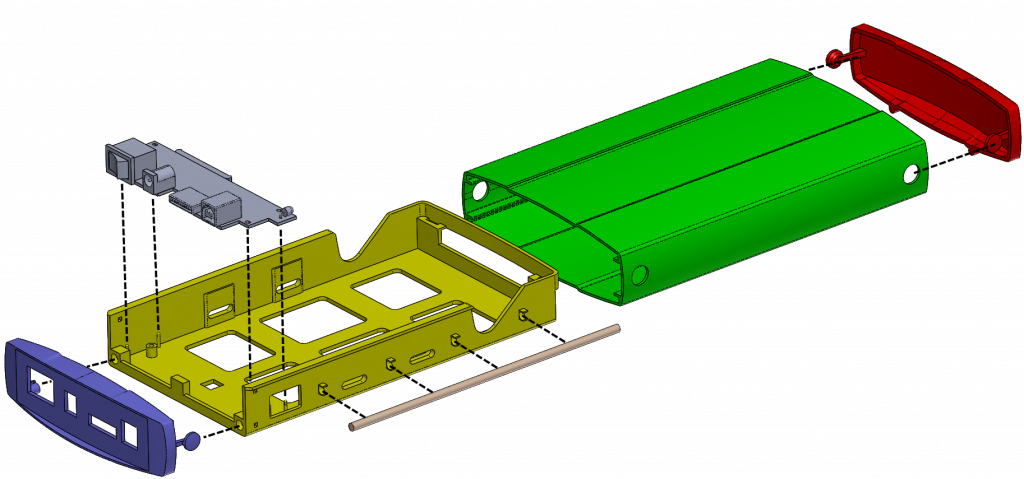

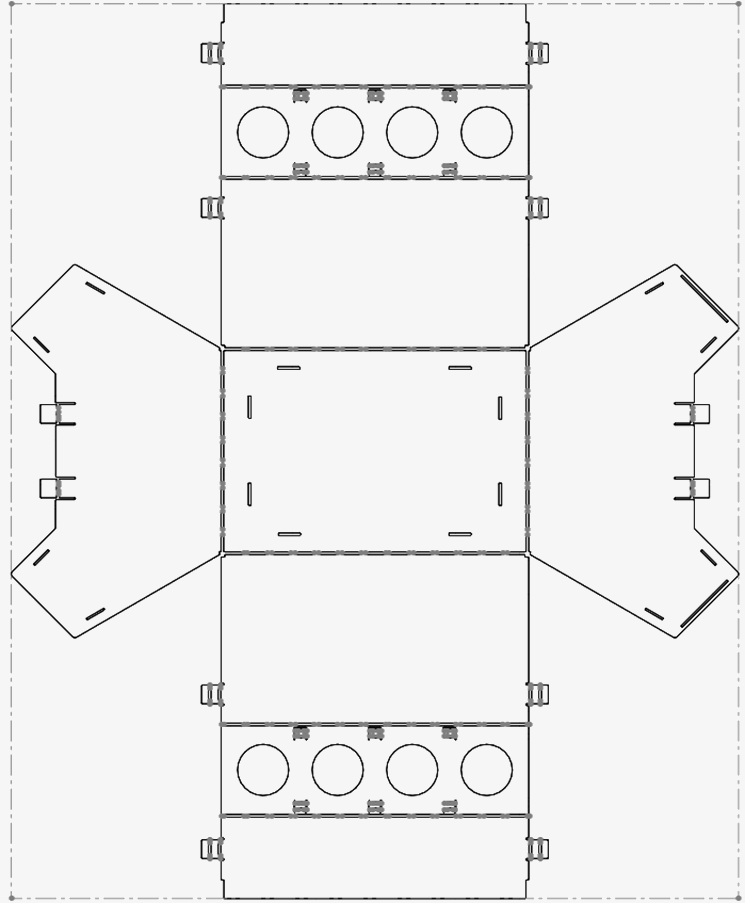

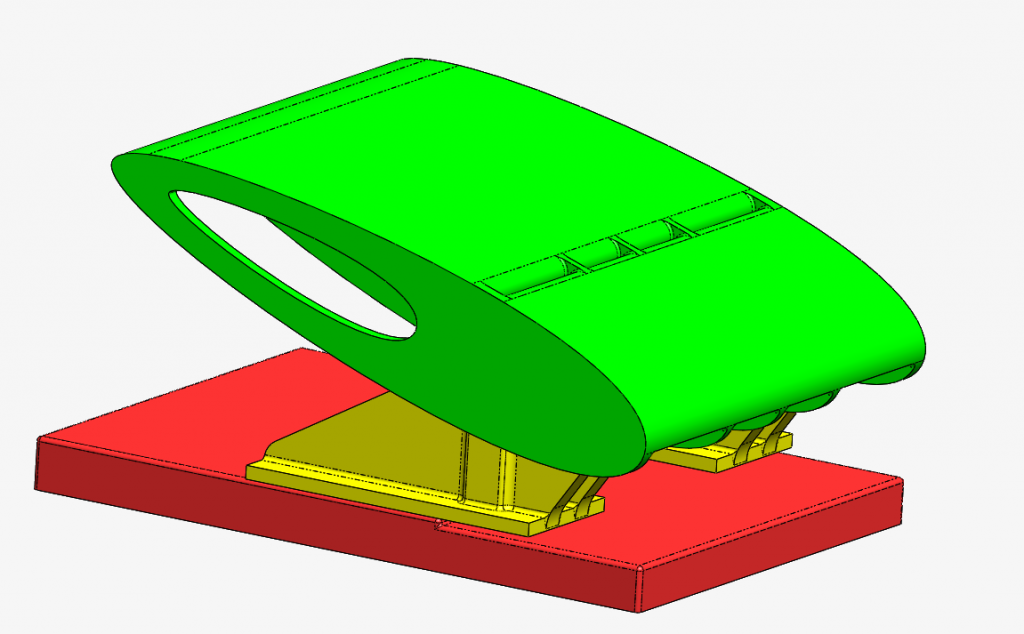

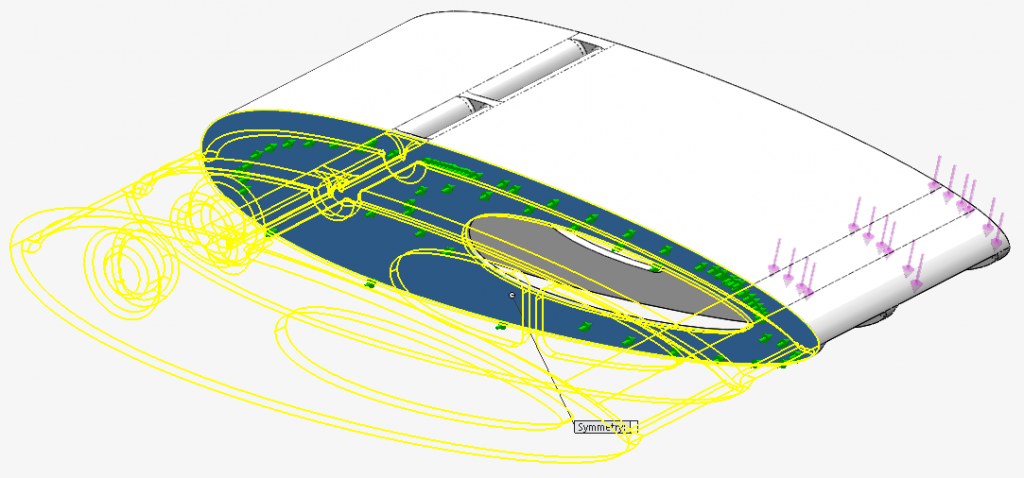

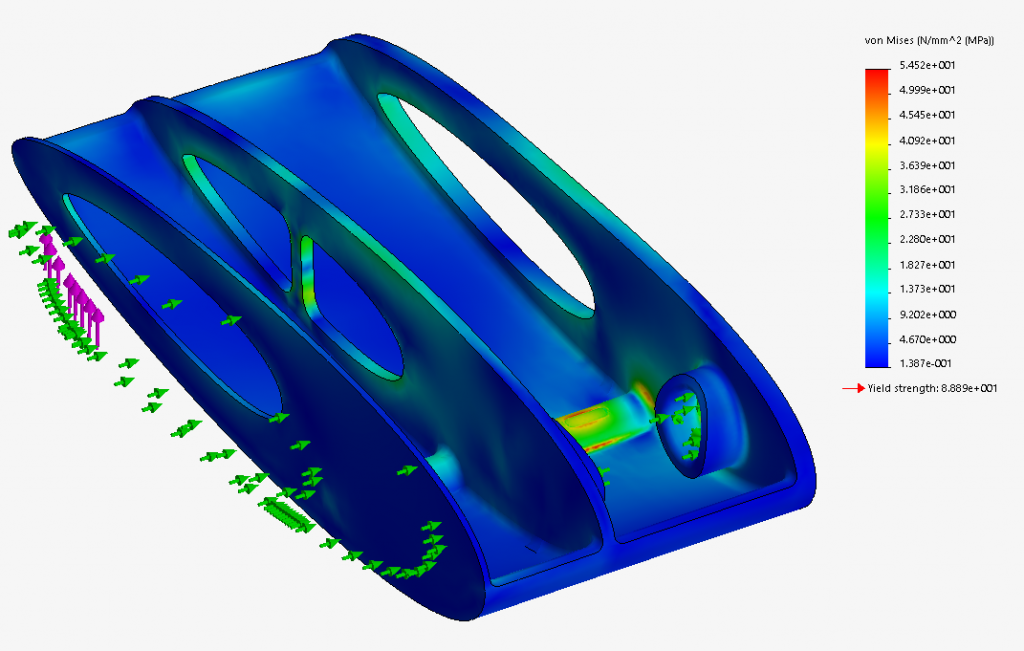

Since I’ve started using it, I have made numerous scripts, doing simple things as copying an annotation to all the sheets within a project, to more complex scripts that export all parts of a certain category in a specified orientation to separate files.

Or a script that exports the full bill of materials of an entire project to a single excel file. In which it automatically adds all pieces profiles, panels, etc. to: m^2/panel color and meters/ profile. So that this file can be directly imported into the ERP system.

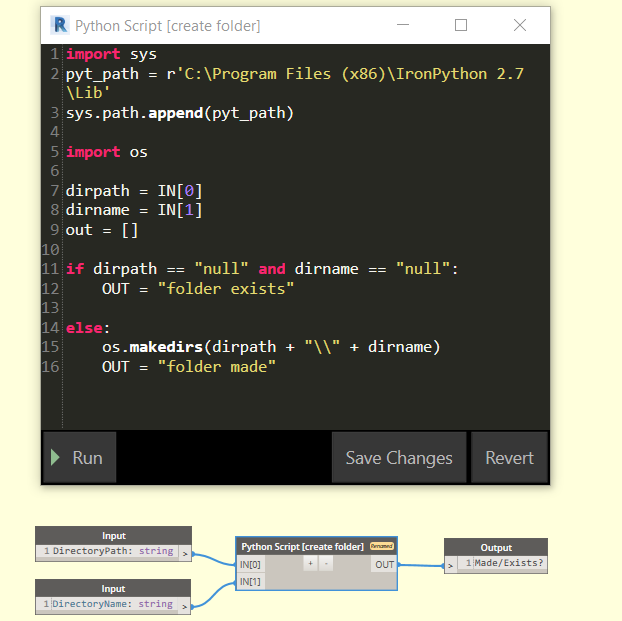

Also, in the past couple of years sometimes I ran into the limitations of Dynamo. So I learned how to make my own custom nodes and use Python scripts to overcome these limitations when necessary.